Battery Management Systems (BMS) are critical components in modern battery systems, responsible for monitoring, protecting, and optimizing battery performance. Proper validation of these systems ensures they meet stringent safety, reliability, and performance requirements across various applications, from consumer electronics to electric vehicles and grid storage solutions.

This comprehensive guide outlines the industry's most成熟 validation processes, covering fundamental concepts, design-stage verification, and manufacturing-phase testing to ensure your BMS performs flawlessly in real-world battery systems applications.

Basic Questions About BMS Validation

What is BMS Validation?

BMS validation is a systematic process of evaluating a Battery Management System to ensure it meets all specified requirements and performs reliably in its intended environment. This process confirms that the BMS can effectively monitor, protect, and optimize battery systems throughout their operational lifecycle.

Why is BMS Validation Important?

Proper validation ensures battery systems operate safely within their design limits, preventing hazardous conditions like overcharging, over-discharging, and thermal runaway. It also verifies performance metrics such as state-of-charge accuracy, balancing capabilities, and communication reliability—critical factors for both consumer safety and product performance.

What are the Key Objectives of BMS Validation?

The primary objectives include verifying that the BMS:

- Accurately monitors cell voltages, temperatures, and currents in battery systems

- Implements proper protection mechanisms against unsafe operating conditions

- Maintains cell balance for optimal performance and longevity

- Provides accurate state estimation (SOC, SOH, SOP)

- Communicates effectively with external systems

- Performs reliably across all operating conditions and throughout the battery lifecycle

- Complies with relevant industry standards and regulations

What Standards Govern BMS Validation?

Several international standards guide BMS validation processes, including ISO 12405 for electric vehicle battery systems, IEC 62133 for safety of secondary cells and batteries, UL 1642 for lithium-ion cells, and UN38.3 for transportation of lithium batteries. Additionally, automotive-specific standards like ISO 26262 (functional safety) apply to BMS used in vehicles.

What are the Main Challenges in BMS Validation?

Challenges include simulating the entire lifecycle of battery systems in accelerated test environments, accounting for cell-to-cell variations, validating performance across extreme temperature ranges, ensuring reliable communication in noisy electrical environments, and maintaining test coverage while managing complex test matrices.

Validation Success Criteria

Design & Development Phase Testing Validation

Requirements Validation

The first step in design-phase validation is ensuring that all requirements are complete, consistent, testable, and aligned with the intended application of the battery systems. This involves reviewing requirements for clarity, checking for conflicts, and verifying that each requirement can be objectively tested.

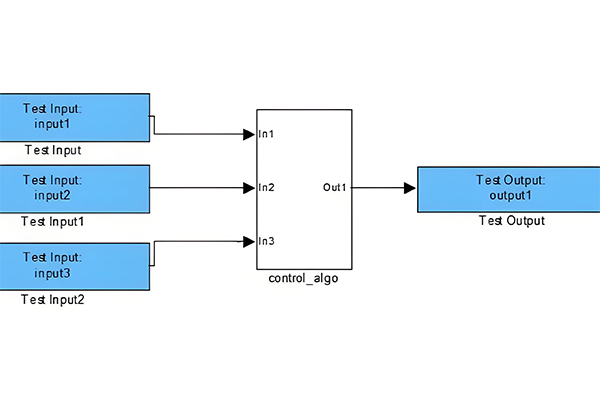

Model-in-the-Loop (MIL) Testing

MIL testing validates the BMS algorithm software using mathematical models of the battery systems and environment. This early-stage testing allows developers to verify control logic, state estimation algorithms, and protection strategies in a simulated environment before any hardware is built. Test cases include:

- SOC estimation accuracy under various operating conditions

- SOH calculation algorithms

- Cell balancing logic verification

- Protection algorithm response to fault conditions

- Charge/discharge control strategy validation

Software-in-the-Loop (SIL) Testing

SIL testing validates the actual BMS software code (or a high-fidelity representation) running on a virtual processor, interacting with simulated battery systems. This step verifies that the code implements the algorithms correctly and checks for issues like:

- Memory management and resource utilization

- Timing and scheduling of software tasks

- Data handling and communication protocols

- Error handling and recovery mechanisms

- Compliance with functional safety requirements

Hardware-in-the-Loop (HIL) Testing

HIL testing involves connecting the actual BMS hardware to a real-time simulator that models the battery systems, load, and environment. This provides a realistic test environment to validate the complete system before integration with physical batteries. Key HIL test scenarios include:

- Hardware response to various sensor inputs

- Actuator control signal verification

- Communication interface testing with other vehicle systems

- Power consumption and efficiency measurements

- Electromagnetic compatibility (EMC) testing

- Fault injection testing for all sensor and communication paths

Prototype Validation with Actual Battery Packs

Before moving to production, the BMS must be validated with actual battery systems in a controlled laboratory environment. This final design-phase validation includes:

- Calibration of SOC and SOH algorithms with real cells

- Cell balancing performance verification

- Charge and discharge cycle testing

- Thermal management validation under various load conditions

- End-of-charge and end-of-discharge behavior verification

- Performance testing across temperature extremes

- Long-term cyclic aging effects on BMS performance

Design Review and Verification

Throughout the design and development phase, formal design reviews ensure that all requirements are addressed and that validation activities have been properly executed. This includes reviewing test plans, test results, and documentation to verify that the BMS design meets all specified requirements for the target battery systems.

Development Phase Validation Process

Progressive validation stages for BMS design and development

Test Coverage by Development Stage

Manufacturing Phase Testing Validation

Incoming Component Inspection

Before assembly, all electronic components used in BMS production must undergo rigorous inspection to ensure they meet specification requirements. This includes verifying component authenticity, checking for physical damage, and confirming electrical parameters. Critical components for battery systems such as microcontrollers, sensors, MOSFETs, and capacitors receive special attention due to their impact on overall BMS performance and safety.

PCB Assembly Testing

After printed circuit board (PCB) assembly, several tests verify the manufacturing quality:

- Visual inspection using automated optical inspection (AOI) systems

- Solder paste inspection (SPI) to verify proper solder application

- In-circuit testing (ICT) to verify component values, correct placement, and solder connections

- Flying probe testing for high-density boards where traditional ICT is impractical

- Power-up testing to verify basic functionality without damaging components

Functional Testing

Each completed BMS undergoes comprehensive functional testing to ensure it operates according to specifications. This includes:

- Boot sequence verification and firmware version check

- Sensor calibration verification for voltage, current, and temperature measurements

- Communication interface testing (CAN, LIN, Ethernet, etc.)

- Protection function validation (overvoltage, undervoltage, overcurrent, overtemperature)

- Cell balancing functionality verification

- PWM output and control signal testing

- Memory and data storage verification

Functional testing ensures that each BMS unit performs all required functions correctly before integration into battery systems.

Environmental Stress Screening

A sample of production units undergoes environmental stress screening (ESS) to identify early-life failures and ensure robust performance in harsh conditions. This includes:

- Temperature cycling between extreme high and low values

- Vibration testing across various frequencies and amplitudes

- Thermal shock testing to verify component integrity

- Humidity testing to check for moisture ingress and corrosion resistance

ESS helps ensure that BMS units can withstand the environmental conditions they will encounter in operational battery systems throughout their service life.

Electrical Safety Testing

To ensure compliance with safety standards and protect users, BMS units undergo rigorous electrical safety testing:

- Insulation resistance testing between high-voltage and low-voltage circuits

- Dielectric strength (hipot) testing to verify insulation integrity

- Ground continuity testing to ensure proper grounding

- Short circuit protection verification

- Overvoltage protection testing

End-of-Line Testing

The final step in manufacturing validation is end-of-line testing, which confirms that each BMS is fully functional and ready for integration into battery systems. This comprehensive test includes:

- Full functional test as per specifications

- Calibration verification and final adjustment if needed

- Software configuration check to ensure correct parameters for the target application

- Label verification and traceability information recording

- Final visual inspection

Only BMS units that pass all end-of-line tests are approved for integration into production battery systems.

Statistical Process Control

Throughout the manufacturing process, statistical process control (SPC) methods monitor key quality metrics to ensure consistent production quality. This includes tracking test results, identifying trends, and implementing corrective actions before significant issues arise. SPC helps maintain the high level of quality required for BMS units used in critical battery systems applications.

Manufacturing Test Sequence

Comprehensive testing ensures quality in BMS production