BMS Hardware Design Excellence

Comprehensive engineering solutions for Battery Management Systems, featuring advanced battery control module technology and industry-leading design methodologies.

Hardware Overall Scheme Design

The Hardware Overall Scheme Design serves as the foundational blueprint for any Battery Management System (BMS), outlining the complete architecture and integration strategy for all components. This phase involves defining system requirements based on application specifics, whether for automotive, industrial, or energy storage applications. A well-designed overall scheme ensures that the BMS can effectively monitor, protect, and optimize battery performance throughout its lifecycle.

Central to this design is the battery control module, which acts as the intelligence hub of the BMS. The battery control module coordinates all other system components, processing data from sensors and executing control algorithms to maintain optimal battery conditions. During the overall scheme design, engineers must determine the appropriate processing power, communication interfaces, and I/O capabilities required for the battery control module to meet system demands.

Key considerations in this phase include:

- Definition of functional requirements and performance metrics

- Selection of appropriate microcontroller units (MCUs) for the battery control module

- Determination of sensor placement and data acquisition strategies

- Design of communication protocols (CAN, LIN, Ethernet) for system integration

- Thermal management strategy for all components, including the battery control module

- Physical layout planning for optimal signal integrity and EMI/EMC performance

- Redundancy and fault tolerance considerations

The overall scheme design must balance performance, cost, reliability, and manufacturability. It typically involves creating block diagrams, system architecture documents, and initial component selection lists. Simulation tools are often employed to validate the proposed architecture before moving to detailed design phases. The battery control module specifications are finalized during this stage, establishing the processing capabilities and functional boundaries that will guide subsequent design decisions.

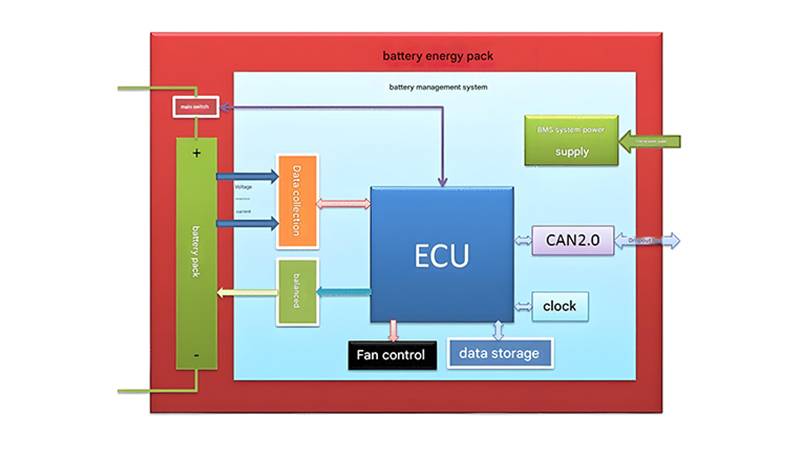

BMS Hardware Architecture

Diagram illustrating the overall hardware scheme with the battery control module at its core, connecting to sensing, power, communication, and protection subsystems.

System Requirements Matrix

| Requirement Category | Key Specifications | Relevance to battery control module |

|---|---|---|

| Voltage Monitoring | ±1mV accuracy, 1-24 cells per channel | Primary data input for control algorithms |

| Current Measurement | ±0.5% accuracy, range -500A to +500A | Used for SOC calculation and protection |

| Temperature Sensing | ±1°C accuracy, up to 16 sensors | Critical for thermal management algorithms |

| Processing Power | 32-bit MCU, ≥100MHz, ≥256KB Flash | Determines computational capabilities |

| Communication | CAN 2.0B, LIN, optional Ethernet | Enables data exchange with external systems |

Power System Output and Protection Design

The Power System Output and Protection Design is critical for ensuring safe and reliable operation of the BMS and connected battery pack. This subsystem is responsible for regulating power distribution within the BMS, providing stable voltages to sensitive components like the battery control module, while implementing robust protection mechanisms against fault conditions.

The power system typically includes multiple voltage rails to accommodate different components: a 3.3V rail for microcontrollers and digital circuits within the battery control module, a 5V rail for sensors and communication interfaces, and potentially higher voltage rails for drivers and actuators. Designers must carefully calculate power requirements for each rail, considering both steady-state and transient conditions.

Protection mechanisms are paramount in BMS power design. These include:

- Overvoltage protection (OVP) to prevent damage from voltage spikes

- Undervoltage lockout (UVLO) to ensure proper operation during low-voltage conditions

- Overcurrent protection (OCP) with adjustable trip points for different subsystems

- Short-circuit protection (SCP) to limit current in fault situations

- Reverse polarity protection to prevent damage from incorrect connections

- Thermal shutdown to protect components during excessive temperature conditions

The battery control module plays a supervisory role in the power system, monitoring voltage levels and current flows through dedicated sense circuits. In the event of a fault, the battery control module can trigger protective actions such as disabling power outputs, activating cooling systems, or isolating the battery pack. Power system design must account for worst-case scenarios, including load dumps, transient voltage spikes, and extreme temperature variations.

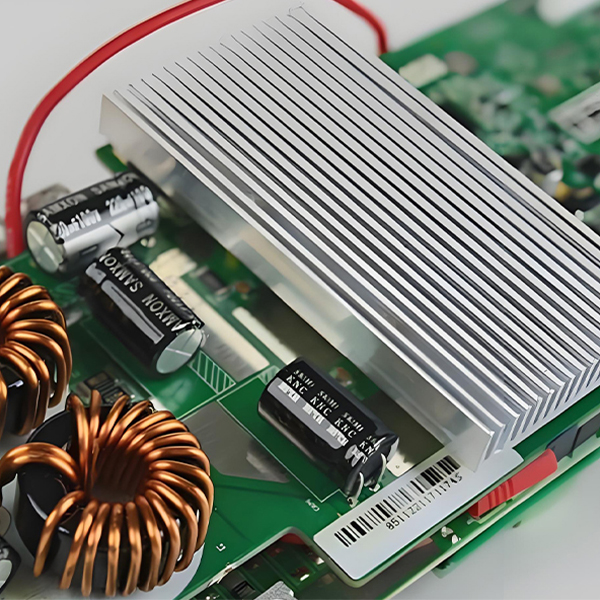

Efficiency is another key consideration, as power losses generate heat that must be managed. Switch-mode power supplies (SMPS) are commonly used for their high efficiency, though linear regulators may be employed in noise-sensitive areas. Layout techniques such as proper grounding, power plane design, and component placement are critical for minimizing noise and ensuring stable operation of the battery control module and other sensitive components.

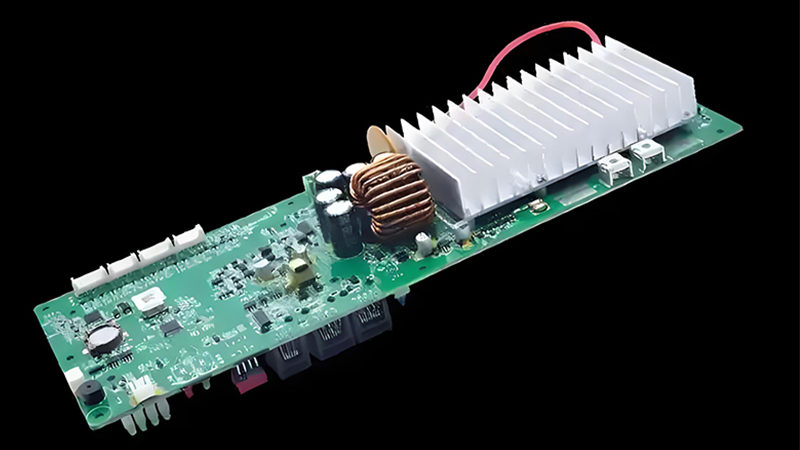

Power Distribution and Protection Schema

Schematic representation of the power system showing multiple voltage rails, protection circuits, and their interface with the battery control module.

Protection Circuit Response Characteristics

The chart illustrates typical response times of various protection mechanisms, with the battery control module providing supervisory control and system-level response.

Topology Design

Topology Design refers to the arrangement and interconnection of components within the BMS hardware architecture. This critical design phase determines how the battery control module interacts with other system components, including cell monitoring circuits, current sensors, communication interfaces, and power management subsystems. The chosen topology directly impacts system performance, reliability, cost, and scalability.

Several common BMS topologies are employed in industry, each with distinct advantages and trade-offs:

Centralized Topology

In a centralized topology, all functions including cell monitoring, current measurement, and control algorithms are integrated into a single main board. The battery control module serves as the central processing unit, directly connected to all sensors and actuators.

Advantages include simplified communication, lower latency between measurements and control actions, and potentially lower cost for small to medium-sized battery packs. Disadvantages may include increased wiring complexity and challenges in thermal management as the number of cells increases.

Distributed Topology

A distributed topology utilizes multiple cell monitoring units (CMUs) placed close to battery cells, with each CMU communicating with a central battery control module. This approach reduces wiring complexity and improves signal integrity by minimizing the distance between sensors and cells.

Benefits include easier scalability for large battery packs, improved thermal management through distributed heat generation, and enhanced fault isolation. Challenges include ensuring reliable communication between CMUs and the battery control module, and maintaining synchronization across distributed measurements.

Modular Topology

Modular topology combines aspects of both centralized and distributed approaches, using standardized modules that can be combined to accommodate different battery pack configurations. The battery control module typically manages multiple identical modules, each responsible for a section of the battery pack.

This approach offers excellent scalability, simplified manufacturing, and easier maintenance and repair. It also facilitates design reuse across multiple product lines. The main challenges involve ensuring consistent performance across modules and managing the communication overhead between the battery control module and each module.

Centralized Topology

Single-board design with integrated battery control module directly connected to all system components.

Distributed Topology

Decentralized architecture with remote monitoring units and a central battery control module.